Connection technologies for our plugs and sockets

Our plugs and sockets are equipped with different connection technologies for easy, safe and time-saving installation. Here you will find an overview of our user-friendly connection technologies ErgoCONTACT, SafeCONTACT, TwinCONTACT and screw contact.

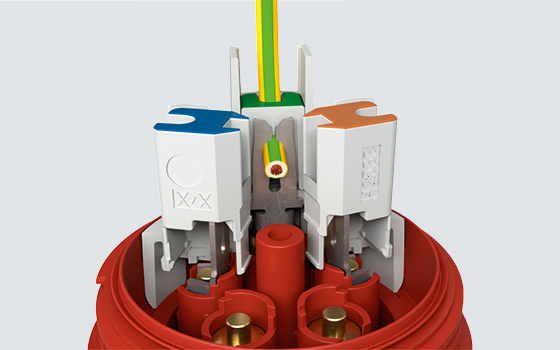

Screw terminal connection technology ErgoCONTACT

Our PowerTOP® Xtra product solutions in 16 and 32 A feature our innovative and convenient screw connection technology ErgoCONTACT. It allows and easy, safe and ergonomical installation: Instead of entering from the side, the screwdriver is placed straight, directing the pressure towards the grab handle. An additional guide collar also supports the screw trajectory to reduce the risk of injury by slipping. Each contact only requires one screw - these are captive combination head screws that can be fixed with a Philips head or flat head screwdriver. All of the screws are pointing in the same direction. This way you do not have to turn and move your hand around to fix each contact which saves time during installation.

With ErgoCONTACT, the screwdriver is applied straight rather than from the side - this makes it easier to achieve the required torque and the screwdriving pressure is aimed directly into the handle. All screws point in the same direction. This means you no longer have to turn the front part in your hand to tighten the contact screws of the individual poles one after the other - and you save time.

Curved conductor guide channels guide the conductor ends easily and safely into the contacts.

The screw path is additionally supported by a guide collar - which prevents slipping and minimises the risk of injury.

Only one screw needs to be used per contact - a captive combination head screw that is permanently integrated into the guide collar ex works and can be operated with a Phillips or slotted screwdriver. The fact that only one screw needs to be used per contact simplifies installation and saves you time during assembly.

Screwless insulation displacement technology SafeCONTACT

Our PowerTOP® Xtra plugs and sockets in 16 and 32 A are available as the PowerTOP® Xtra S version featuring our insulation displacement technology SafeCONTACT. You do not have to remove the insulation or prepare the conductor which saves time during installation and maintenance.

Insert the conductor without stripping, lever down the terminals with a screwdriver - done!

In a single operation, the insulation is separated by levering down and a secure contact connection is established.

Screwless spring terminal technology TwinCONTACT

MENNEKES wall mounted and panel mounted sockets in 16 and 32 A are equipped with out time-saving spring terminal technology TwinCONTACT. You simply remove the insulation from the wire and insert the conductor into the socket. Coded twin clamps securely hold the conductor in the right place. If you want to release the conductor again, you can easily disconnect it by pressing the red release button.

Screw contact connection technology 63 and 125 A

In the 63 and 125 A models, the contact screws are integrated into the front part of the plug, coupling or socket next to the guide collar to save space.

The stripped conductors are simply inserted - they can be used with or without ferrules.

Two contact screws ensure that the ladder is held securely in place. These are tightened crosswise and hold the ladder in position for the long term.

FAQs, technical support, training and factory visits

Do you have questions about topics around electrotechnology? Have a look at our FAQ site! If you cannot find your answers there, our technical support will help you.

Do you wish detailed training for our plugs, connectors and sockets or want to take a look at our production facilities in a factory visit? Just ask our training team!